Torsion Springs

Wire Springs

A torsion spring is a spring that works by torsion or twisting; that is, a flexible elastic object that stores mechanical energy when it is twisted. When it is twisted, it exerts a force (actually torque) in the opposite direction, proportional to the amount (angle) it is twisted. There are two types. A torsion bar is a straight bar of metal or rubber that is subjected to twisting (shear stress) about its axis by torque applied at its ends. A more delicate form used in sensitive instruments, called a torsion fiber consists of a fiber of silk, glass, or quartz under tension, that is twisted about its axis.

The other type, a helical torsion spring, is a metal rod or wire in the shape of a helix (coil) that is subjected to twisting about the axis of the coil by sideways forces (bending moments) applied to its ends, twisting the coil tighter. This terminology can be confusing because in a helical torsion spring the forces acting on the wire are actually bending stresses, not torsional (shear) stresses.

Some familiar examples of uses are the strong, helical torsion springs that operate clothespins and traditional spring-loaded-bar type mousetraps. Other uses are in the large, coiled torsion springs used to counterbalance the weight of garage doors, and a similar system is used to assist in opening the trunk (boot) cover on some sedans. Small, coiled torsion springs are often used to operate pop-up doors found on small consumer goods like digital cameras and compact disc players.

Other more specific uses:

- A torsion bar suspension is a thick, steel torsion-bar spring attached to the body of a vehicle at one end and to a lever arm which attaches to the axle of the wheel at the other. It absorbs road shocks as the wheel goes over bumps and rough road surfaces, cushioning the ride for the passengers. Torsion-bar suspensions are used in many modern cars and trucks, as well as military vehicles.

- The sway bar used in many vehicle suspension systems also uses the torsion spring principle.

- The torsion pendulum used in torsion pendulum clocks is a wheel-shaped weight suspended from its center by a wire torsion spring. The weight rotates about the axis of the spring, twisting it, instead of swinging like an ordinary pendulum. The force of the spring reverses the direction of rotation, so the wheel oscillates back and forth, driven at the top by the clock's gears.

- The torsion catapult or mangonel is a medieval siege engine invented by the ancient Greeks. It uses a torsion spring consisting of twisted ropes to swing an arm that throws a heavy missile at the enemy with great force.

- The balance spring or hairspring in mechanical watches is a fine, spiral-shaped torsion spring that pushes the balance wheel back toward its center position as it rotates back and forth. The balance wheel and spring function similarly to the torsion pendulum above in keeping time for the watch.

- The D'Arsonval movement used in mechanical pointer-type meters to measure electric current is a type of torsion balance (see below). A coil of wire attached to the pointer twists in a magnetic field against the resistance of a torsion spring. Hooke's law ensures that the angle of the pointer is proportional to the current.

- A DMD or digital micromirror device chip is at the heart of many video projectors. It uses hundreds of thousands of tiny mirrors on tiny torsion springs fabricated on a silicon surface to reflect light onto the screen, forming the image.

Choosing the Right Springs Manufacturer Matters!

Put Us To Work For You!

Design Considerations: Torsion Springs

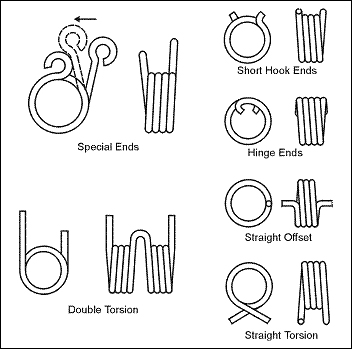

End Configurations

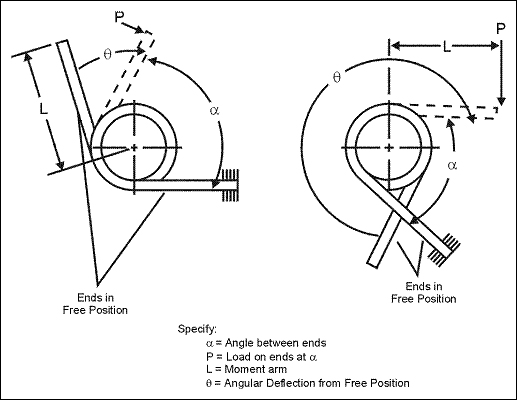

Some of the more common end configurations available are shown. Special configurations are available on request. In designing ends, it is important to recall that bends, loaded to decrease their radius of curvature, have favorable residual stresses. They can operate at higher applied stress levels than bends that increase the radius by loading. Frequently, spring performance is limited because the sharply bent ends have greater stress than the body. Torsion springs are subject to surging and resonance phenomena. The natural frequency n for a torsion spring with one end fixed is:

Spring Rate

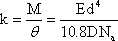

Spring Rate Spring rate for helical round wire torsion springs is given by:

The 10.8 factor is greater than the theoretical factor of 10.2 to allow for friction between adjacent spring coils and between the spring body and the arbor. This factor is based on experience and has been found to be satisfactory. Loads for torsion springs should be specified at a fixed angular position and not at a fixed deflection from the free position. Presently, there is no standard way to test loads for torsion springs.

Custom Torsion Springs